Nano-Clear Technology

Nano-Clear Properties Overview

Conventional aromatic paint systems cannot provide long-term corrosion protection in severe service environments. Aromatic paint formulations cannot withstand UV and weathering. Fiberglass also oxidizes under UV. Oxidization = degradation.

Nano-Clear Industrial Coating is an aliphatic polyurethane/polyurea hybrid formulated for long-term protection against UV degradation, chemical attack and abrasion. Nano-Clear penetrates deep into the substrate (paint, powder coat, fiberglass, concrete, wood) to form a highly cross-linked protective hard topcoat surface. Nano-Clear Industrial Coating also contains UV absorbers that prevent UV degradation of the substrate by absorbing harmful UV rays.

What makes Nano-Clear Better?

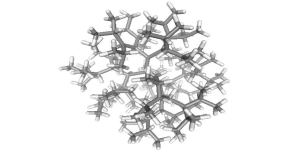

Crosslink density is the concentration of chemical bonds within a polymer. The higher concentrations of chemical bonds within a polymer the better the physical properties of the cured product.

Dynamic Mechanical Thermal Analysis (DMTA) is utilized to calculate the “crosslink density” of coating polymers. Nano-Clear contains three times the cross-link density of alternative topcoats. That means Nano-Clear provides physical properties other topcoats can’t match.

Nano-Clear Coatings do not contain any nanoparticles like many marketed “nano” coatings. Rather, all Nano-Clear Coatings rely on crosslink density to exceed OEM technical specifications.

Nano-Clear Industrial coating protects the substrate from UV degradation by absorbing harmful UV rays.

Nano-Clear has 3X higher crosslink density over leading automotive OEM factory applied “high bake” clear coatings.